Strength of a family business

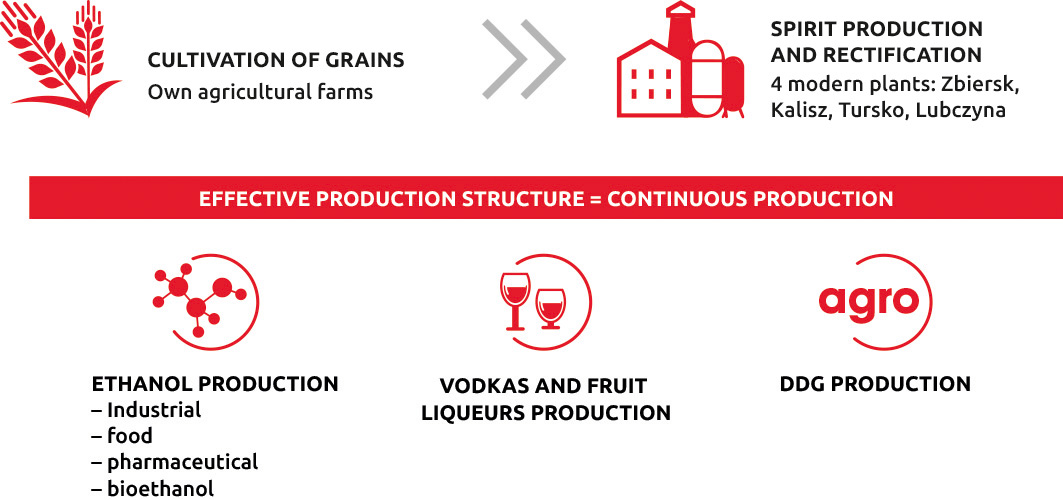

Nearly 30 years ago, we dreamed of creating a modern agricultural company. These dreams have come true and today we make the AWW Group, a friends and family circle of enthusiasts, who know perfectly their profession and its secrets. We specialise in the production of ethanol and bioethanol for chemicals, food and pharmaceuticals markets.

A part of the high-quality ethanol produced is used for our own production of vodkas and liqueurs.

We are a company that has been associated with Wielkopolska for generations: here are our crops, distilleries and modern processing plants. Raw material coming from our fields is processed in modern production plants. Concerned about the quality and safety of our orders, we get involved in every stage of the production process. Cultivating the best farming traditions, we focus on technological development and use modern production lines. We are a company that uses the earth's riches, therefore we know the importance of the awareness and care for the environment.

As far as business is concerned, we focus on traditional values – we value honest exchange of skills, loyalty, and business friendships. New challenges are ahead of us, however the principles remain the same: reliability, honesty and efficiency.

Wiesław Wawrzyniak